Digital Touch Screen Programming

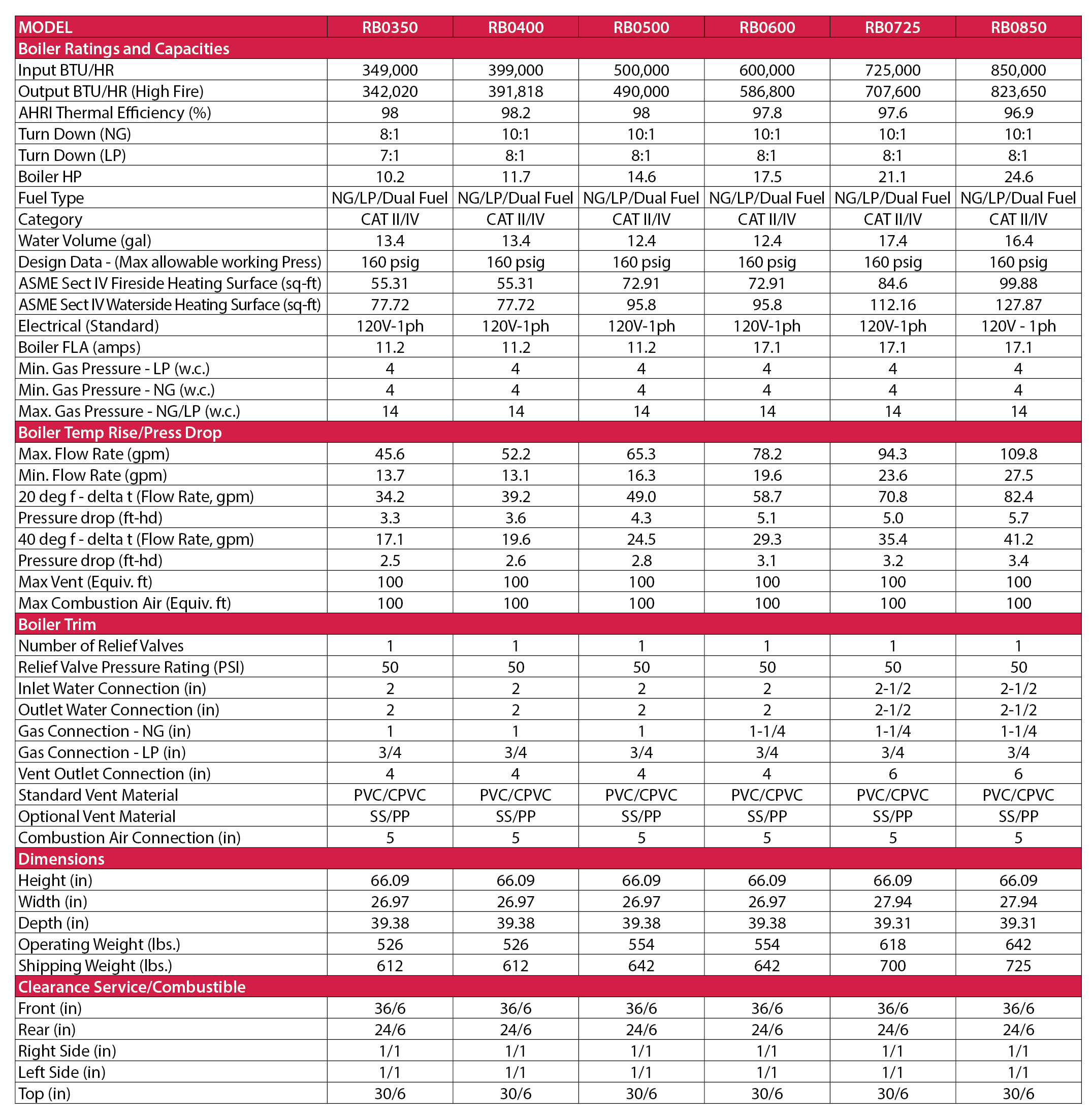

- EnCore Firetube Series Interactive Submittal Data Sheet Set

- EnCore Firetube Series 350 Interactive Submittal Data Sheet

- EnCore Firetube Series 400 Interactive Submittal Data Sheet

- EnCore Firetube Series 500 Interactive Submittal Data Sheet

- EnCore Firetube Series 600 Interactive Submittal Data Sheet

- EnCore Firetube Series 725 Interactive Submittal Data Sheet

- EnCore Firetube Series 850 Interactive Submittal Data Sheet

- EnCore Firetube Series Dual Fuel Interactive Submittal Data Sheet Set

- EnCore Firetube Series 350 Dual Fuel Interactive Submittal Data Sheet

- EnCore Firetube Series 400 Dual Fuel Interactive Submittal Data Sheet

- EnCore Firetube Series 500 Dual Fuel Interactive Submittal Data Sheet

- EnCore Firetube Series 600 Dual Fuel Interactive Submittal Data Sheet

- EnCore Firetube Series 725 Dual Fuel Interactive Submittal Data Sheet

- EnCore Firetube Series 850 Dual Fuel Interactive Submittal Data Sheet

- EnCore 350 Plan View Drawing

- EnCore 350 Plan View Drawing

- EnCore 400 Plan View Drawing

- EnCore 400 Plan View Drawing

- EnCore 500 Plan View Drawing

- EnCore 500 Plan View Drawing

- EnCore 600 Plan View Drawing

- EnCore 600 Plan View Drawing

- EnCore 725 Plan View Drawing

- EnCore 725 Plan View Drawing

- EnCore 850 Plan View Drawing

- EnCore 850 Plan View Drawing

- EnCore 350 Dual Fuel Plan View Drawing

- EnCore 350 Dual Fuel Plan View Drawing

- EnCore 400 Dual Fuel Plan View Drawing

- EnCore 400 Dual Fuel Plan View Drawing

- EnCore 500 Dual Fuel Plan View Drawing

- EnCore 500 Dual Fuel Plan View Drawing

- EnCore 600 Dual Fuel Plan View Drawing

- EnCore 600 Dual Fuel Plan View Drawing

- EnCore 725 Dual Fuel Plan View Drawing

- EnCore 725 Dual Fuel Plan View Drawing

- EnCore 850 Dual Fuel Plan View Drawing

- EnCore 850 Dual Fuel Plan View Drawing