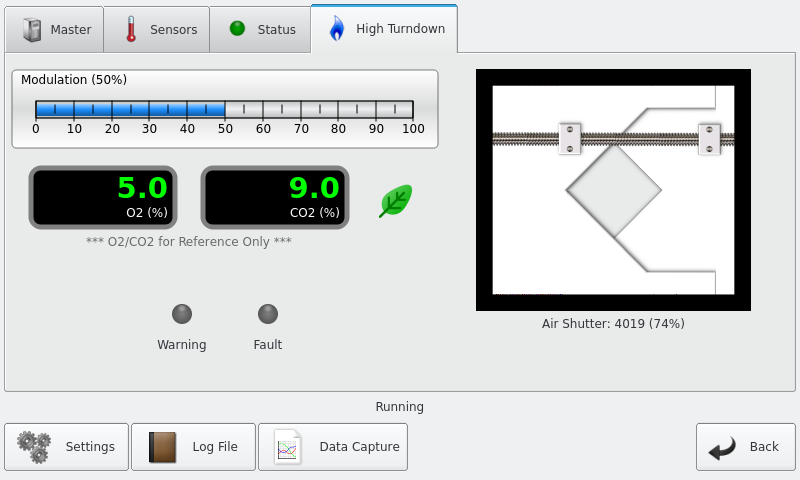

Digital Touch Screen Programming

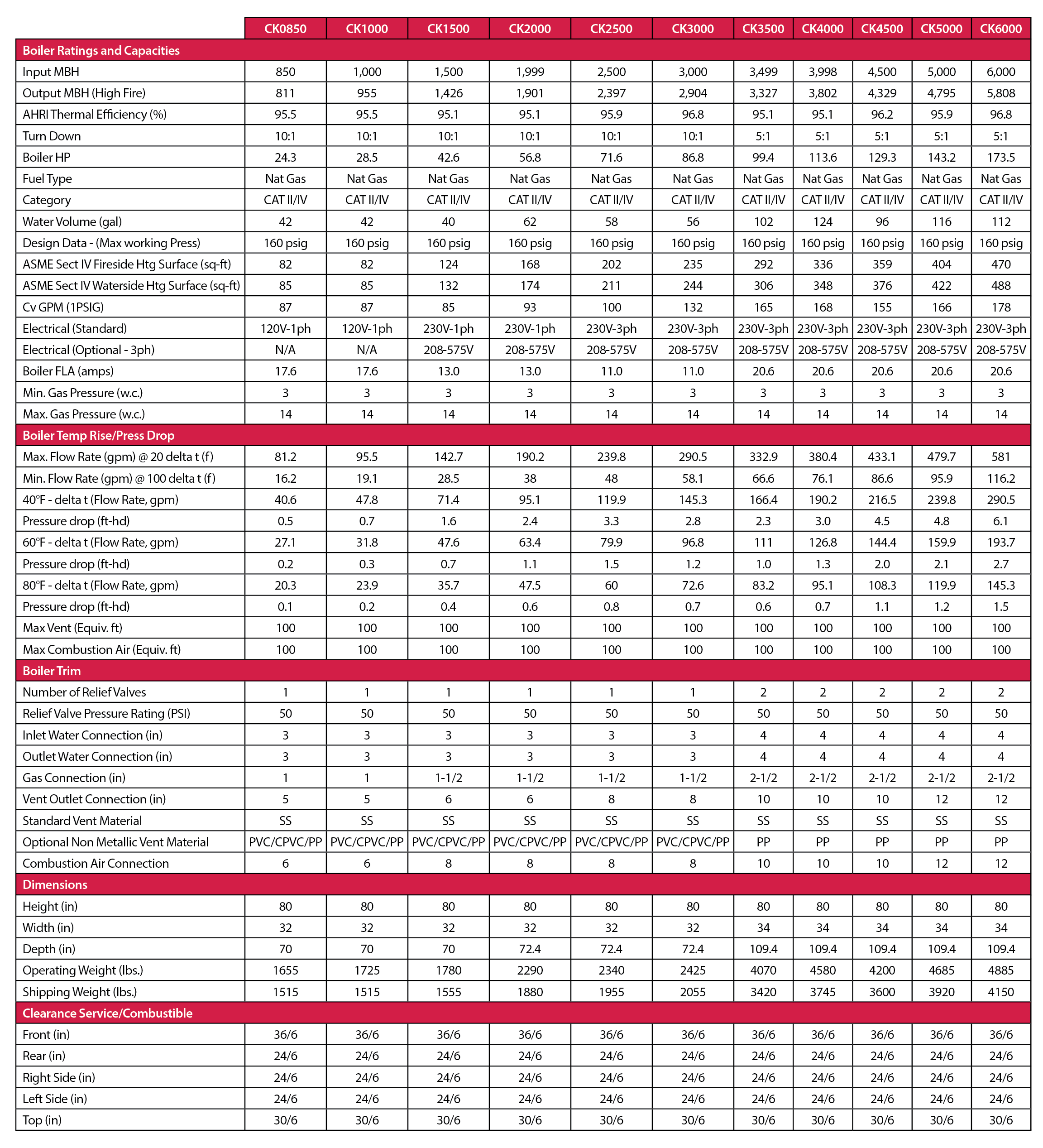

- FlexCore Firetube 1500 Interactive Submittal Data Sheet

- FlexCore Firetube 3000 Interactive Submittal Data Sheet

- FlexCore Firetube 1500 Plan View Drawing

- FlexCore Firetube 1500 Plan View Drawing

- FlexCore Firetube 3000 Plan View Drawing

- FlexCore Firetube 3000 Plan View Drawing

- FlexCore Firetube 2000 Plan View Drawing

- FlexCore Firetube 2000 Plan View Drawing

- FlexCore Firetube 2500 Plan View Drawing

- FlexCore Firetube 2500 Plan View Drawing

- FlexCore Firetube 3500 Plan View Drawing

- FlexCore Firetube 3500 Plan View Drawing

- FlexCore Firetube 4000 Plan View Drawing

- FlexCore Firetube 4000 Plan View Drawing

- FlexCore Firetube 4500 Plan View Drawing

- FlexCore Firetube 4500 Plan View Drawing

- FlexCore Firetube 5000 Plan View Drawing

- FlexCore Firetube 5000 Plan View Drawing

- FlexCore Firetube 6000 Plan View Drawing

- FlexCore Firetube 6000 Plan View Drawing

- FlexCore Firetube 2000 Interactive Submittal Data Sheet

- FlexCore Firetube 2500 Interactive Submittal Data Sheet

- FlexCore Firetube 3500 Interactive Submittal Data Sheet

- FlexCore Firetube 4000 Interactive Submittal Data Sheet

- FlexCore Firetube 4500 Interactive Submittal Data Sheet

- FlexCore Firetube 5000 Interactive Submittal Data Sheet

- FlexCore Firetube 6000 Interactive Submittal Data Sheet

- FlexCore Firetube Series Interactive Submittal Data Sheet Set (SFT)

- FlexCore Firetube 1000 Interactive Submittal Data Sheet

- FlexCore Firetube 850 Interactive Submittal Data Sheet

- FlexCore Firetube 850 Plan View Drawing

- FlexCore Firetube 850 Plan View Drawing

- FlexCore Firetube 1000 Plan View Drawing

- FlexCore Firetube 1000 Plan View Drawing